YK200H Plasma Cutting Machine Cutting Torch

- Information

- Product Description

YK200-H Machine Use Plasma Torch

We supply:

All plasma cutting torch parts (Shield, Retaining cap,Swirl ring, Nozzle, Electrode)

Many brands such as Hypertherm, Thermadyne, Kaliburn, kjellberg, Black Wolf, YK, FY etc

All consumables of different plasma cutting torches (P80, YK100, YK200, YK300, YK330, FY200...)

Features

It's a professional machine use plasma cutting torch

It's a water cooling YK plasma torch:Special design of the water cooling circuit,high improves the torch working life;

Higher cutting speed and productivity:When cut 20mm low carbon steel,the cutting speed is 2.5-3 times higher than the gas cutting;

Lower cutting cost:Better copper materials and hf wire inlay welding processing,highly improves the consumption life;

A ideal replacement of European American plasma torch:With ingenious design and rigorous testing,it proves that this torch fit complex operating environment.

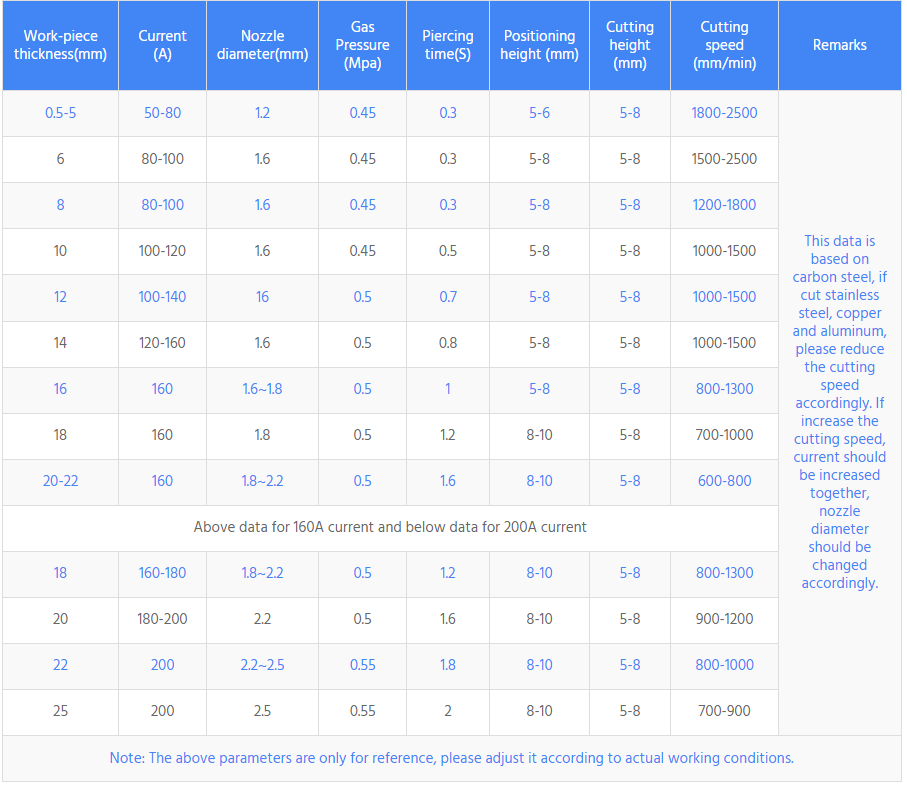

Typical cutting parameters

The piercing thickness up-to 30mm

| Cutting capacity | Cutting thickness | Cutting speed |

Production | 20mm | 1100-1200mm/min |

Production | 14mm | 1600-1850mm/min |

Severance (Edge start) | 50mm | 230mm/min |

| Pierce | 30mm |

Note:The maximum current of this YK plasma torch model is 200A,the recommended working air pressure is 0.45-0.6MPa,the compressed air should be dry,clean and oil-free.

Features

It's a professional machine use plasma cutting torch;

It's a water cooling YK plasma torch:Special design of the water cooling circuit,high improves the torch working life;

Higher cutting speed and productivity:When cut 20mm low carbon steel,the cutting speed is 2.5-3 times higher than the gas cutting;

Lower cutting cost:Better copper materials and hf wire inlay welding processing,highly improves the consumption life;